HP JET FUSION 3D 5200

Expand and scale into mid-volume production environments

HP Jet Fusion 5200 3D Printer, Build Unit, Natural Cooling Unit and Processing Station.

MANUFACTURING PREDICTABILITY

Quality—from fine detail and sharp edges to textures.

Dimensional accuracy and repeatability that rivals industrial tooling—faster.

Functional parts with best-in-class isotropy.

Optimal yield at industrial-level OEE.

Maximize your equipment uptime.

BREAKTHROUGH ECONOMICS

Best-in-class economics and productivity – for production environments.

Uniquely predictable and consistent print time for any type of part.

Centralized job tracking and production fleet Streamlined workflow and HP’s most economical continuous 3D printing.

Flexibility and agility—without injection molding fine-tuning steps.

EXPAND INTO NEW APPLICATIONS AND MARKETS

Address more final part applications with new levels of repeatable accuracy and best-in-class economics.

Produce applications with flexible, elastomeric properties with TPU material. 1

Deliver a breadth of applications for various markets with HP 3D High Reusability PA 11 and PA 12 materials today, and more in the future.2

Address sustainability, with lower carbon footprint 3 parts, and HP 3D materials offering industry-leading reusability. 4

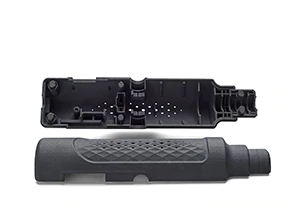

HP 3D High Reusability PA 12

Strong, low cost,10 quality parts

HP 3D High Reusability PP5

enabled by BASF

Chemical resistant,6 weldable, low moisture absorption, functional parts

HP 3D High Reusability PA 12 GB

Stiff, dimensionally stable, quality parts

BASF Ultrasint® 3D TPU01

Produce flexible, functional parts

HP 3D High Reusability PA 11

Ductile,8 quality parts

HP Jet Fusion 5200 Series 3D Automatic Unpacking Station

Achieve consistent unpacking results through an automatic process with an industrial-grade solution.

3D AutoBLAST - Automated Basket Blaster

Tailored to post-process 3D printed parts, the Guyson MultiBlast3D removes residual powder and preserves color with single-use media delivery or process batches with continuous flow.

Girbau 3D Dyeing Solution 6

HP recommended post-processing solution for dye finishing.

HP Jet Fusion 5200 3D Natural Cooling Unit

Designed to remove and cool each build naturally, thereby enabling continuous production.

Hovmand Forklift 5200

HP recommended accessory to remove and place the HP Jet Fusion 5200 3D Natural Cooling Unit from the processing station.

HP Jet Fusion 3D Solution Services

Explore new opportunities to scale production and accelerate growth with support and consultancy from HP.

HP Financial Services

Accelerate your time to value. Enjoy the flexibility to meet both your technology and financial plans while allocating your cash to other priorities.

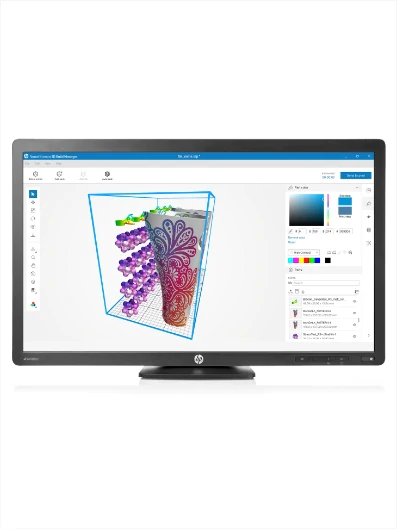

Job preparation and monitoring

All you need to start your 3D printing project — intuitive and powerful software with the essential features to prepare and send your parts to print.

HP 3D Process Control

Dimensional accuracy and repeatability—faster. Flexibility and agility—without injection molding fine-tuning steps.

HP 3D Center

Track, manage, and optimize your 3D operations with remote, real-time monitoring; preventative notifications; and historical data analysis.

HP SmartStream 3D Build Manager

Quickly and easily prepare your jobs for printing with all the elements you need.

Integration with industry-leading solutions

Materialise Build Processor for HP Multi Jet Fusion

Connect with Materialise Magics with Materialise Build Processor for HP Multi Jet Fusion, the industry standard software for professional 3D Printing, to unlock the full potential of your HP 3D printer and manage every step in your production process.

Autodesk® Netfabb® with HP Engine

Provides advanced software for the additive manufacturing of production quality parts. Quality control functions prevent machine errors and enhance your overall process reliability and efficiency.

Founding member of 3MF Consortium

HP is a founding member of the 3MF Consortium—an industry consortium working to define a new 3D printing format that will allow design applications to send full-fidelity 3D models to a mix of other applications, platforms, services and printers.

∗ Specifications subject to change without notice.

∗∗ Material dependent.

Technical specifications

HP Jet Fusion 5200 Series 3D Printers

| Printer performance | Technology | HP Multi Jet Fusion technology |

|---|---|---|

| Effective building volume | 380 x 284 x 380 mm (15 x 11.2 x 15 in) | |

| Building speed | Up to 5058 cm³/hr (309 in³/hr) | |

| Layer thickness | 0.08 mm (0.003 in) | |

| Print resolution (x, y) | 1200 dpi | |

| Job processing resolution (x, y) | 1200 dpi | |

| Dimensions (w x d x h) |

Printer | 2210 x 1268 x 1804 mm (87 x 50 x 71 in) |

| Shipping | 2300 x 1325 x 2027 mm (91 x 52 x 80 in) | |

| Operating area | 3700 x 3700 x 2500 mm (146 x 146 x 99 in) | |

| Weight | Printer | 880 kg (1940 lb) |

| Build Unit | 140.5 kg (309.7 lb) | |

| Shipping | 1037.5 kg (2287 lb) | |

| Network | Gigabit Ethernet (10/100/1000Base-T), supporting the following standards: TCP/IP, DHCP (IPv4 only), TLS/SSL | |

| Processor and memory | Memory | 32 GB DDR4 |

| Processor | Intel® Core™ i7 7770 (3.6 GHz, up to 4.2 GHz) | |

| Hard disk | 1TB HDD SED (AES-256 encrypted) | |

| 1TB SDD SED (AES-256 encrypted), TGC-OPAL 2.01 compliant | ||

| Software | HP 3D Process Control, HP 3D Center, HP SmartStream 3D Build Manager, HP SmartStream 3D Command Center | |

| Supported file formats | 3MF, STL, OBJ, and VRML (v2.0) | |

| Certified third-party software | Autodesk® Netfabb® with HP Workspace, Materialise Build Processor for HP Multi Jet Fusion technology, Siemens NX AM for HP Multi Jet Fusion technology | |

| Power | Consumption | 12 kw |

| Requirements | 380-415 V (line-to-line), 50 A max, 50/60 Hz, 200-240 V (line-to-line), 80 A max, 50/60 Hz | |

| Certification | Safety | IEC 60950-1+A1+A2 compliant; United States and Canada (UL listed); EU (LVD and MD compliant, EN 60950-1, EN 12100-1, EN 60204-1, and EN 1010) |

| Electromagnetic | Compliant with Class A requirements, including: USA (FCC rules), Canada (ICES), EU (EMC Directive), Australia (ACMA), New Zealand (RSM), Korea (KCC) | |

| Warranty & Service coverage included | One-year limited hardware warranty |

HP Jet Fusion 5200 Series 3D Processing Stations

| Features | Automated mixing and loading with ultrasonic sieving and accessible sieve mesh; semi-manual unpacking; high-temperature unpacking; automated external storage tank; optional trained self-service deep-cleaning; optional cooling unit | |

|---|---|---|

| Dimensions (w x d x h) |

Processing Station | 2990 x 934 x 2400 mm (117.7 x 36.8 x 94.5 in) |

| Shipping | 2389 x 1176 x 2182 mm (94 x 46.3 x 85.9 in) | |

| Operating area | 3190 x 2434 x 2500 mm (125.6 x 95.8 x 99 in) | |

| Weight | Processing Station | 485 kg (1069 lb) |

| Loaded | 724 kg (1596 lb) | |

| Shipping | 620 kg (1366 lb) | |

| Power | Consumption | 2.6 kW (typical) |

| Requirements | Input voltage single pase 200-240 V (line-to-line) 19 A max, 50/60 Hz (line-to-neutral) 14 A max, 50 Hz | |

| Certification | Safety | UL 2011, UL508A, NFPA 70 / NFPA 79, C22.2 NO. 14-13 compliant; United States and Canada (UL listed); EU (MD compliant, EN 60204-1, EN 12100-1, EN 1127-1, EN-ISO 11201 and EN 1010) |

| Electromagnetic | Compliant with Class A requirements, including: USA (FCC rules), Canada (ICES), EU (EMC Directive), Australia (ACMA), New Zealand (RSM), Korea (KCC) | |

| Environmental | REACH | |

| Warranty & Service coverage included | One-year limited hardware warranty |

HP Jet Fusion 3D Printing

1. Available only for the HP Jet Fusion 5200/4200 Series 3D Printing Solutions.

2. Supported industrial management systems: AMFG, LINK3D, Siemens NX AM, Siemens Opcenter. Access to additional data modules available only for the HP Jet Fusion 5200 Series 3D Printing Solution. Additional purchases required.

3. Supported additive processes: HP Multi Jet Fusion (polymers), binder jetting (polymers, metals, ceramics), powder bed fusion DMLS/SLS/SHS (metals), EBM (metals), SLS (polymers), FDM (polymers), SLA/DLP (polymers), LOM (composites, ceramics, glass), CBAM (composites, glass, ceramics). Compatible software. Additional purchase required.

4. Available only for the HP Jet Fusion 5200 Series 3D Printing Solution. This software is sold as an HP 3D Solution Service. For more information visit https://h20195.www2.hp.com/v2/GetDocument.aspx?docname=4AA7-7931EEW

5. Based on internal HP testing, May 2020. HP Jet Fusion 3D Printing Solutions using HP 3D High Reusability PP enabled by BASF provide up to 100% powder reusability ratio, producing functional parts batch after batch. For testing, material is aged in real printing conditions and reclaimed powder is tracked by generations (worst case for reusability). Parts are then made from each subsequent generation and tested for mechanical properties and accuracy showing no degradation of properties up to three generations of use.

6. Based on internal HP testing, May 2020, with tests for mechanical property retention, dimensional stability, and weight change after 7- and 30-day immersion with acids, bases, organic solvents, and aqueous solutions.

7. HP 3D High Reusability PA 11 image is data courtesy of NACAR

8. HP Jet Fusion 3D Printing Solutions using HP 3D High Reusability PA 11 provide up to 70% powder reusability ratio, producing functional parts batch after batch. For testing, material is aged in real printing conditions and powder is tracked by generations (worst case for reusability). Parts are then made from each generation and tested for mechanical properties and accuracy.

9. Testing according to ASTM D638, ASTM D256, and ASTM D648 using HDT at different loads with a 3D scanner for dimensional accuracy. Testing monitored using statistical process controls.

10. HP 3D High Reusability PA 12 image is data courtesy of Addit.ion.

11. HP Jet Fusion 3D Printing Solutions using HP 3D High Reusability PA 12 provide up to 80% powder reusability ratio, producing functional parts batch after batch. For testing, material is aged in real printing conditions and powder is tracked by generations (worst case for reusability). Parts are then made from each generation and tested for mechanical properties and accuracy.

12. Supplies price, and maintenance costs recommended by manufacturer. Cost criteria: printing 1.4 full build chambers of parts per day/5 days per week over 1 year of 30 cm3 parts at 10% packing density on Fast print mode using HP 3D High Reusability PA 12 material, and the powder reusability ratio recommended by manufacturer, and printing under certain build conditions and part geometries.

13. HP 3D High Reusability PA 12 GB image is data courtesy of NACAR

14. HP Jet Fusion 3D Printing Solutions using HP 3D High Reusability PA 12 Glass Beads provide up to 70% powder reusability ratio, producing functional parts batch after batch. For testing, material is aged in real printing conditions and powder is tracked by generations (worst case for reusability). Parts are then made from each generation and tested for mechanical properties and accuracy.

15. BASF Ultrasint® TPU01 image is data courtesy of Kupol.

16. HP does not design, manufacture or sell the Girbau product or provide any warranty for the Girbau products. HP believes that the information herein is correct based on the current state of scientific knowledge and as the date of its publication, however, to the maximum extent permitted by law HP EXPRESSLY DISCLAIMS ANY REPRESENTATIONS AND WARRANTIES OF ANY KIND, WHETHER EXPRESS OR IMPLIED, AS TO THE ACCURACY, COMPLETENESS, NON-INFRINGEMENT, MERCHANTABILITY AND/OR FITNESS FOR A PARTICULAR PURPOSE (EVEN IF HP IS AWARE OF SUCH PURPOSE) WITH RESPECT TO ANY INFORMATION PROVIDED. Except to the extent that exclusion is prevented by law, HP shall not be liable for technical or editorial errors or omissions, and damages or losses of any kind or nature that result from the use of or reliance upon this information, which is subject to change without notice. Recipients of the Girbau product are responsible for determining the suitability of Girbau products with HP Jet Fusion 3D products, ensuring compliance with applicable laws and regulations, and being aware that other safety or performance considerations may arise when using, handling or storing the pro.

17. Data courtesy of Meidai