Premium Data Optimization Software

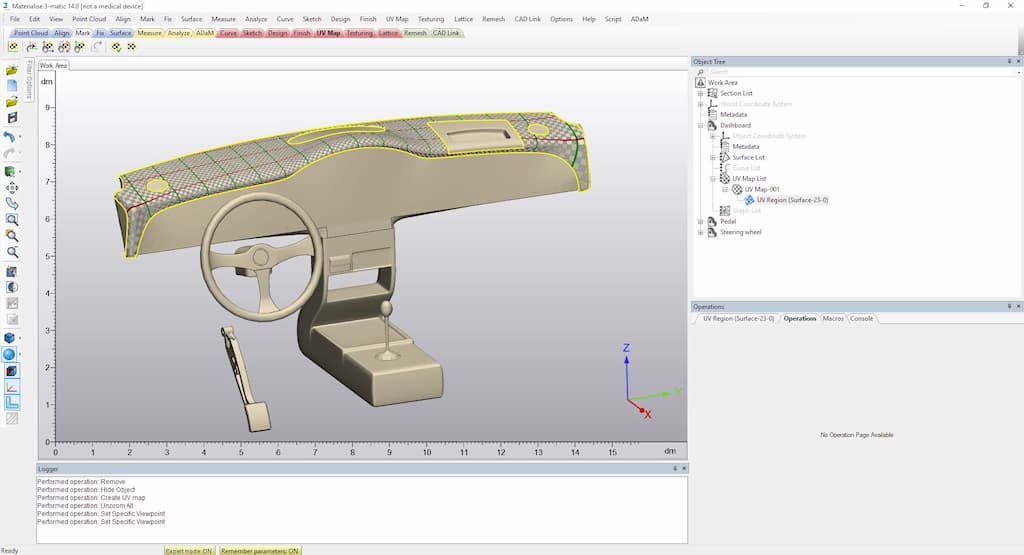

A great design for Additive Manufacturing usually starts with a CAD design, a topology optimized model, a simulation, or scanned data as input. To benefit from the possibilities that 3D Printing offers, you need a versatile tool to make design modifications on the mesh level. With Materialise 3-matic, you can clean up rough data for simulation or convert your mesh back to CAD. In addition, it allows you to enhance your design by creating 3D textures, lattice structures and conformal structures, ready for Additive Manufacturing.

Experience Unprecedented Freedom of Design

With our design optimization software, you can fully personalize your products and create models that were impossible to produce with traditional manufacturing methods.

Save Time and Costs with Lattice Structures

Materialise 3-matic allows you to create stunning lattice designs, leading to lower material costs and less printing time. These optimized lattices outperform solid blocks of material in numerous ways.

Master Part Properties

Master the physical properties of your part. Change aerodynamic, acoustic and cushioning properties or characteristics, increase grip or control the density of your part with porous structures.

Rely on a Complete Platform

Materialise 3-matic is integrated with Materialise Magics and other solutions from our extensive software suite.

Discover the full suiteMODULES

Do you want to apply functional textures to your model or reduce the weight of your part with a lattice structure? Choose the module that fits your needs.

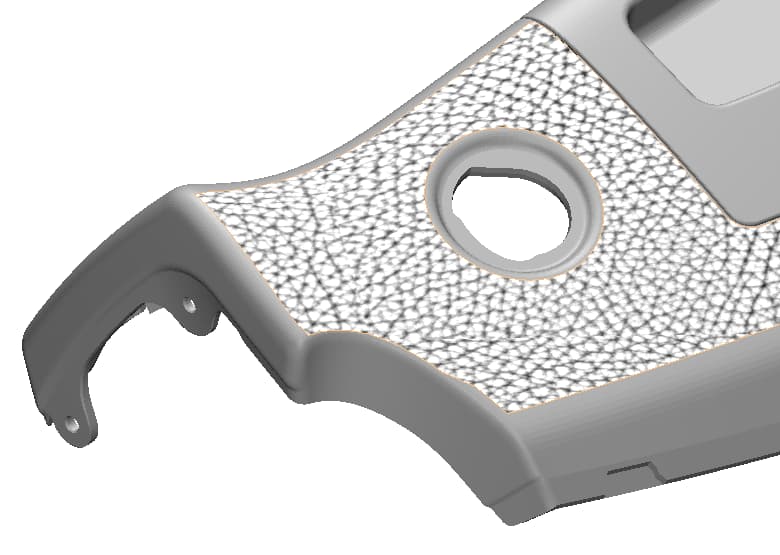

Texturing Module

The look and feel of a part is crucial to the success of a product design. It largely defines the esthetics of a part, but can also lead to added functionality or improved performance. With the Materialise 3-matic Texturing Module, you can efficiently create 3D textures, perforations and patterns directly on the STL file (which can later be printed with RP/AM technology). In addition, you have the flexibility to quickly change and preview 3D textured components without having to share your designs with external suppliers.

Use the Texturing Module to:

- Individualize your designs

- Improve grip

- Avoid finishing work (since layers are masked)

- Improve aerodynamic properties

- Change acoustic properties

Key Benefits of the Texturing Module

♦ Ensure printability and avoid excessive STL file sizes with slice-based technology

♦ Handle highly complex surfaces efficiently

♦ Have full control over the creation of new textures and how they are applied on your model

♦ Reduce lead time by incorporating textures in your design rather than as a post-processing step

♦ Keep confidential 3D designs or finished parts in your business

♦ Use textures to reduce the visibility of the slices in the printed part, minimizing the need for sanding and improving the overall looks

Lattice Module

Nature uses precisely designed structures to create shapes that fit the needs of strength, flexibility and rigidness while still keeping them as light as possible. Manufacturing similar lattice structures has always been challenging and often impossible to achieve with traditional manufacturing technologies.

One of the key advantages of 3D Printing is the flexibility to create shapes which are impossible or too costly to produce with traditional technologies. The Materialise 3-matic Lattice Module realizes one of the most promising potentials of the 3D printing industry: optimizing your designs and translating them into components with a lattice structure.

Key Benefits of the Lattice Module:

♦ Choose from a wide variety of structures

♦ Add or design your own unit structures

♦ Apply it internally, following the surface or other options

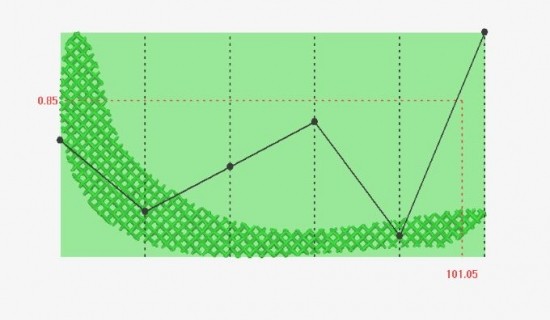

♦ Optimize your designs based on analysis

♦ Process complex designs with the slice-based technology of the Build Processor

Scripting Module

Automating your workflow is your best bet to save time and increase consistency and productivity. The Scripting module is designed to do a lot of the legwork for you by automating repetitive work, leaving you free to focus on more interesting tasks. Once workflows are codified, you will be able to work in a highly efficient way that minimizes the risk of human error and allows you to get the job done a whole lot faster.

Mass customization is tangible with this module: scale up your work from one custom design to 10, 20, or even hundreds of designs, whilst still maintaining the option to customize every individual design when needed.

Python allows for customizing user interfaces that interact with 3-matic, making the UX more user-friendly and consistent.

To ensure that you hit the ground running, the Scripting module includes extended API documentation as well as tutorials and our Software team is always there to provide support.

Use the Scripting module to:

- Create time-saving automated workflows

- Mass customize your designs

- Scale up your research

- Tailor 3-matic to your needs

Key benefits of the Scripting module:

♦ Achieve more consistency results between different users

♦ Avoid human error

♦ Do more design iterations/variations

♦ Create a workflow that could easily be expanded and adapted for future projects

Import Module

With the Materialise 3-matic Import Module, you can create STL data from native and non-native CAD data, including IGES, VDA, Vrml, Catia V4, V5 and V6, UG, Pro-E and STEP files. In addition, it offers import and meshing functionality for point cloud data.

With hollowed designs, the Materialise Magics Structures Module enables you to add holes so that excess powder can be removed. The module features a structures library and can be used to alter structures to meet a variety of objectives, including saving powder, controlling the temperature, reinforcing your design and much more.

CAD Link Module

The Materialise 3-matic CAD Link Module gives you the possibility to easily bring your file back to CAD. As a combination of the segmentation tools and intelligent automatic splitting, this module offers you the complete solution to convert STL files to IGES or STEP.

Included in the conversion is a feature recognition where the basic analytical shapes will be converted with the correct parameters, while the organic regions will be converted to NURBS to obtain a fully parametric design.

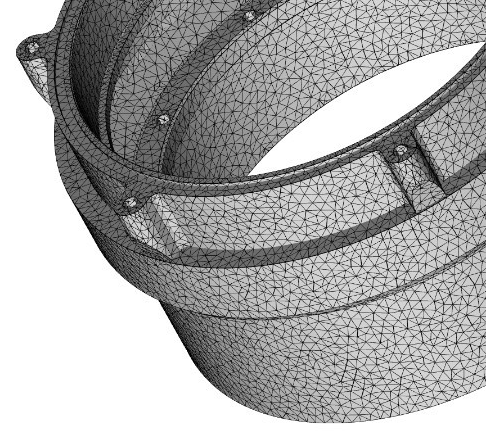

Remesh Module

The Materialise 3-matic Remesh Module allows you to fully prepare your parts for CAE applications. The surface mesh is optimized through different manual and automatic remesh operations, which control the quality and size of the part’s surface triangulation.

The Remesh Module also offers a volume meshing functionality, which lets you create Tet4 and Tet10 volume meshes. These surface meshes and volume meshes can be exported to Fluent, Ansys, Abaqus, Comsol, Patran and Nastran file formats. Additionally, the lattice beams designed in Materialise 3-matic can be exported to Abaqus and Optistruct, which allows you to fully analyze the structural integrity of your lightweight part before printing.

PRODDUCT INFORMATION

Minimum System Requirements

Hardware

Intel® Core™ 2 Duo / AMD Athlon™ X2 AM2 or equivalent

4 GB RAM

DirectX® 11.0 compliant graphics card with 1GB RAM

5 GB free hard disk space

Resolution of 1280x1024

Software

Windows® 7 SP1 (including KB2533623 and KB2999226) – 64bit

Internet Explorer® 10

PDF viewer

.NET framework 4.5.2 (or higher)

Recommended System Requirements

Hardware

Third generation Intel® Core™ i5/i7 or equivalent

16 GB RAM

DirectX® 11.0 compliant AMD Radeon/NVIDIA® GeForce® card with 2GB RAM

20 GB free hard disk space

Resolution of 1680x1050 or higher

Software

Windows® 10 version 1803 - 64bit

Internet Explorer® 10

PDF viewer

.NET framework 4.5.2 (or higher)

Licensing

Interested in purchasing a Materialise 3-matic license? We offer limited, perpetual, floating and classroom licenses.

- Limited (or annual) license: The software will be active for a period of one year after the activation of the license. Maintenance services are included with this license

- Perpetual license: Your license agreement includes maintenance for the first year and shall continue until terminated. If not terminated by either party, the perpetual license is valid for an unlimited period of time

- Floating license: A floating license authorizes use of the software by an agreed upon number of concurrent end-users on one or several computers

- Classroom license: Universities and research institutes that use Materialise 3-matic exclusively for academic purposes can use a classroom license

∗ Specifications subject to change without notice.

∗∗ Material dependent.